A Buyer's Complete Guide to PVC & Sustainable Alternative Cosmetic Bag Manufacturing

You want a clear, shiny cosmetic bag, so you consider PVC. But you are worried about its environmental impact and how it reflects on your brand in today's green-conscious market.

PVC is cheap but raises environmental and health concerns. Sustainable alternatives like RPET, vegan leather, and organic cotton offer better brand alignment and meet consumer demand, though they often cost more and have different performance characteristics.

My company's slogan is "Green Mission, Global Win-Win." This is not just a phrase; it is the core of how we operate. I believe that great design and sustainability can and must go hand-in-hand. I have seen talented designers like you, Jennie, struggle with this exact material choice. You want the function and look of a material like PVC, but your brand's values, and your customers' expectations, are pushing for a better way. I want you to know that a better way exists. This guide will walk you through the options, helping you make a choice that is good for your design, your brand, and the planet.

How do PVC, RPET, Vegan Leather, and Organic Cotton compare?

Choosing a material is confusing. You need to balance the look, the feel, the cost, and the sustainability story, but it is hard to compare them side-by-side.

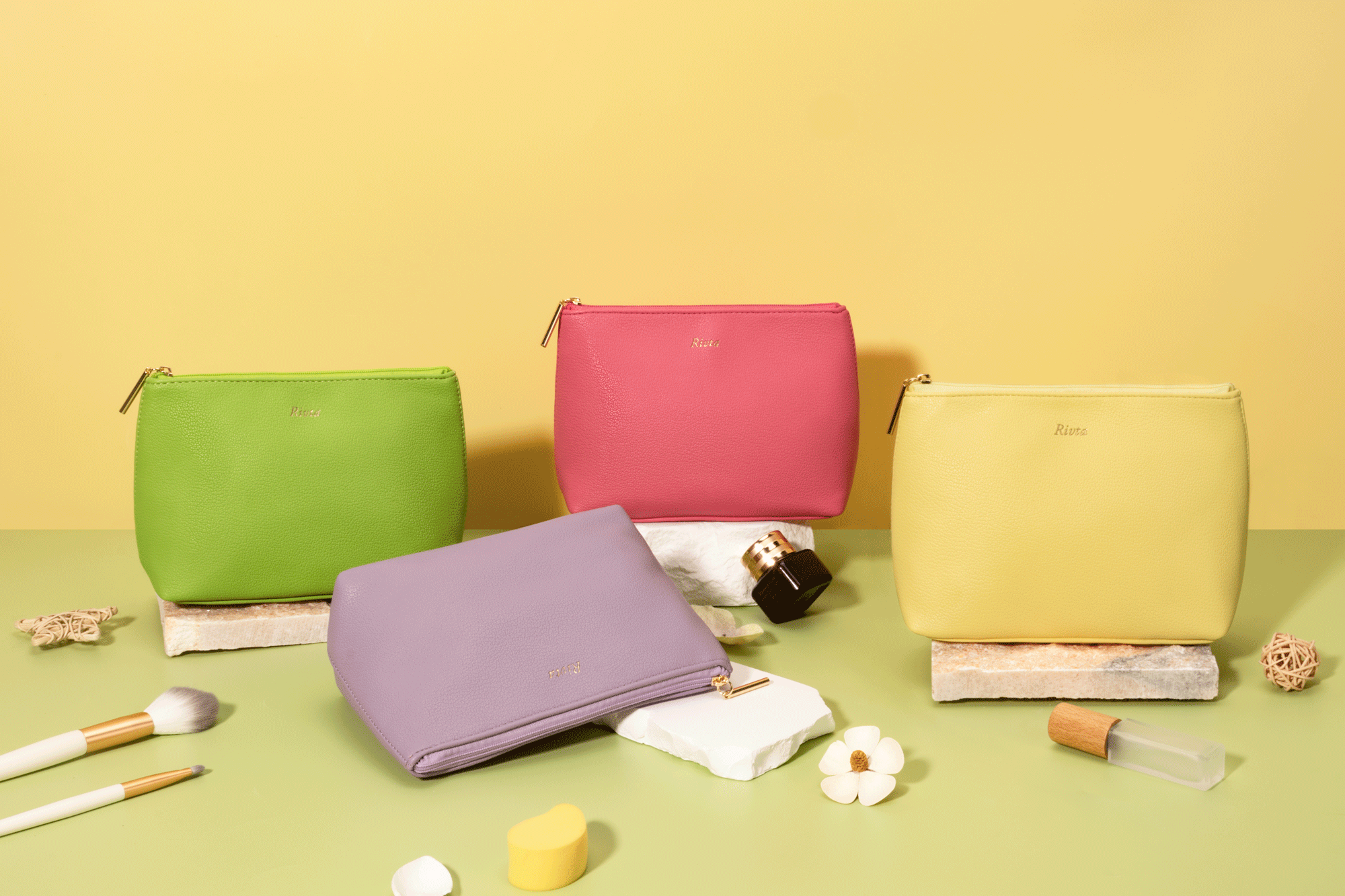

PVC is the lowest-cost clear option. RPET is the best clear, sustainable alternative. Vegan leathers offer a luxe feel with varying eco-credentials. Organic cotton provides a natural, soft touch.

As a manufacturer, I handle these materials every single day. I understand their unique properties and how they perform. A few years ago, a brand came to me wanting to create a clear travel pouch. Their initial request was for PVC because it was familiar and inexpensive. I understood their goal, but I also knew their customer base was young and eco-conscious. I suggested we make a second sample using clear RPET made from recycled plastic bottles. When they saw the two samples side-by-side, the choice was clear. The RPET had the same crystal-clear look they wanted, but it came with a powerful sustainability story they could share with their customers. It was a perfect "win-win" and represented the kind of co-creation I love to be a part of.

A Head-to-Head Comparison

| Material | Look & Feel | Sustainability Story | Best Use Case |

|---|---|---|---|

| PVC | Clear, shiny, plastic-feel. Can feel cheap. Easy to wipe clean. | Low. A petroleum-based plastic. Contains phthalates. Not easily recycled. | Budget-friendly clear pouches where sustainability is not a primary brand focus. |

| RPET | Clear and shiny or a woven fabric feel. High-quality look. | High. Made from recycled plastic bottles. Reduces landfill waste and energy use. (Look for GRS certification). | The best direct, eco-friendly alternative to clear PVC. Also great for durable printed bags. |

| PU Vegan Leather | Smooth, luxe, leather-like. Huge range of textures and finishes. | Medium. It is still a plastic, but it is free of the worst chemicals in PVC. Look for recycled PU for a better story. | Creating high-end, structured bags that need to look and feel premium and are cruelty-free. |

| Organic Cotton | Soft, natural texture. Can be dyed in any color. | High. Grown without synthetic pesticides. Uses less water than conventional cotton. (Look for GOTS certification). | Soft pouches, dust bags, and casual totes. Great for brands with a natural or wellness focus. |

How does sustainability impact your brand and bottom line?

You think switching to sustainable materials is just an added expense. You are worried it will hurt your margins without providing a real return on your investment.

Using sustainable materials is a powerful marketing tool. It builds brand loyalty with conscious consumers, differentiates you from competitors, and can even justify a premium price point, ultimately benefiting your bottom line.

The conversation has changed. Ten years ago, "eco-friendly" was a niche market. Today, it is a core expectation for many consumers, especially in the beauty space. I had a long-term client who produced a simple cotton canvas bag with us for years. We suggested they switch to GOTS-certified organic cotton. The cost was slightly higher, but they embraced the change. They timed the launch for Earth Day and built a whole marketing campaign around their "Green Mission." They explained what organic cotton meant and why they made the switch. The customer response was amazing. They sold out of the new bag, and the positive social media engagement was huge. It was not just a new bag; it was a statement that strengthened their brand community.

The Return on Investment (ROI) of Going Green

- Customer Loyalty: Modern consumers, especially Millennials and Gen Z, actively seek out and stay loyal to brands that share their values. Sustainability is a key value.

- Brand Differentiation: In a crowded market, having a genuine commitment to sustainability makes you stand out. A bag made from recycled materials is more memorable than another generic plastic pouch.

- Premium Pricing: Consumers are often willing to pay more for a product they know is made responsibly. An organic cotton or RPET bag has a higher perceived value than a standard polyester or PVC bag.

- Future-Proofing Your Brand: Governments are introducing more regulations around plastics and waste. Building your supply chain around sustainable materials now puts you ahead of future requirements and protects you from potential compliance issues.

What does "eco-friendly" truly mean in a cosmetic bag?

The term "eco-friendly" is everywhere, and it can feel meaningless. You are worried about "greenwashing" and want to know what makes a product genuinely sustainable.

True eco-friendliness in a cosmetic bag considers the full life cycle. It means using sustainable raw materials, employing responsible production processes, and planning for the product's end-of-life through recyclability or biodegradability.

Breaking Down "Eco-Friendly"

A truly sustainable bag excels in three areas:

1. Material Sourcing

It starts with the raw materials.

- Recycled Content: Using materials like RPET (from plastic bottles) or recycled cotton. This is proven by GRS (Global Recycled Standard) certification.

- Organic Content: Using materials like organic cotton or hemp grown without synthetic fertilizers or pesticides. This is proven by GOTS (Global Organic Textile Standard) certification.

- Bio-Based Materials: Using innovative materials made from plants, like cactus or apple leather.

2. Production Process

How the bag is made matters just as much.

- Water & Energy Use: Responsible factories invest in technology to reduce consumption.

- Chemicals & Dyes: Using non-toxic, certified dyes (like OEKO-TEX certified) and avoiding harmful chemicals like phthalates and heavy metals.

- Social Compliance: Ensuring the factory provides safe conditions and fair wages for workers, often verified by a BSCI or Sedex audit.

3. End-of-Life

What happens after the customer is done with the bag?

- Recyclability: Designing the bag so it can be easily disassembled and recycled. For example, using a single type of material (a "mono-material" design).

- Biodegradability: Choosing materials like cotton that will naturally break down over time, unlike plastic.

What are the manufacturing challenges and opportunities with sustainable materials?

You are excited about using green materials, but you have heard they can be expensive, inconsistent, and hard to work with, potentially causing production delays or quality issues.

Sustainable materials can have higher costs and require specific manufacturing expertise. However, this challenge presents an opportunity for innovation in design and for building a deeper, more collaborative relationship with a knowledgeable manufacturing partner.

Common Challenges

- Cost: Recycled and organic certified materials are almost always more expensive than their conventional counterparts due to the added processing and certification costs.

- Consistency: Natural fibers like cotton or jute can have slight variations in color and texture from batch to batch.

- Technical Performance: Some eco-materials might not have the same tensile strength or water resistance as a synthetic alternative, requiring adjustments to the bag's design.

- Minimums (MOQs): Custom-developed sustainable materials often come with high minimum order quantities from the fabric mills.

Hidden Opportunities

- Innovation: These challenges force us to be more creative. We can discover new design techniques and constructions that become a signature of your product.

- Authenticity: The slight variations in natural materials can be turned into a marketing story. It shows the product is not mass-produced plastic but something more unique and authentic.

- Deeper Partnerships: Overcoming these challenges together builds a much stronger relationship between a brand and a manufacturer. You are not just a client; you are a co-creator.

- Market Leadership: Being one of the first brands to successfully use a new sustainable material makes you a leader in the industry.

Conclusion

Choosing sustainable materials over PVC is a choice for better branding and a healthier planet. It is a collaborative journey that, with the right partner, leads to innovative products and business success.